Oct 16, 2018 · And that's one of the smallest batteries on the market: BMW's i3 has a 42 kWh battery, Mercedes's upcoming EQC crossover will have a 80 kWh battery, and Audi's e-tron will come in at 95 kWh. With such heavy batteries, an electric car's carbon footprint can grow quitePerfect even beyond the showroom, depending on how it's charged.

If you need even more power, the 20V MAX* Battery Adapter lets you use 20V MAX* batteries in most 18V tools. *Maximum initial battery voltage (measured without a workload) is 12, 20, 40, 60 and 120 volts. Nominal voltage is 10.8, 18, 36, 54 and 108. 120V MAX* is based on using 2 DEWALT 60V MAX* lithium-ion batteries combined. The DEWALT ® 40V

The extensive range of AGVs and LGVs produced by Elettric80 offers a rapid response to the needs of factories which require the complete integration of material flows: from the finished products to the implementation of different types of high-density auto warehouses (Smart and Crane Store), as well as packaging materials to be supplied to production lines.

and lithium for LDV Li-ion battery (LIB) materials. Its estimated use from 2014 through 2016 was between 15,000 metric tons (mt) and 24,000 mt of cobalt, and between 15,000 Mt and 40,000 Mt of lithium carbonate equivalent. Other top markets for cobalt and lithium for LDV LIB materials include Japan, South Korea, and Belgium.

The Battery Testing, Analysis, and Design activity supports several complementary but crucial aspects of the battery development program. The activity’s goal is to support the development of a U.S. domestic advanced battery industry whose products can meet electric drive vehicle performance targets.

Jan 24, 2022 · Forquer describes yet another core competency for Kirchhoff Automotive: edge welding using the gas-metal-arc or laser-welding process, which, he explains, the company developed originally to allow for shorter flanges and more robust weld joints on cross-car beams, and now uses to fabricate battery cases, bumpers and CMSs.

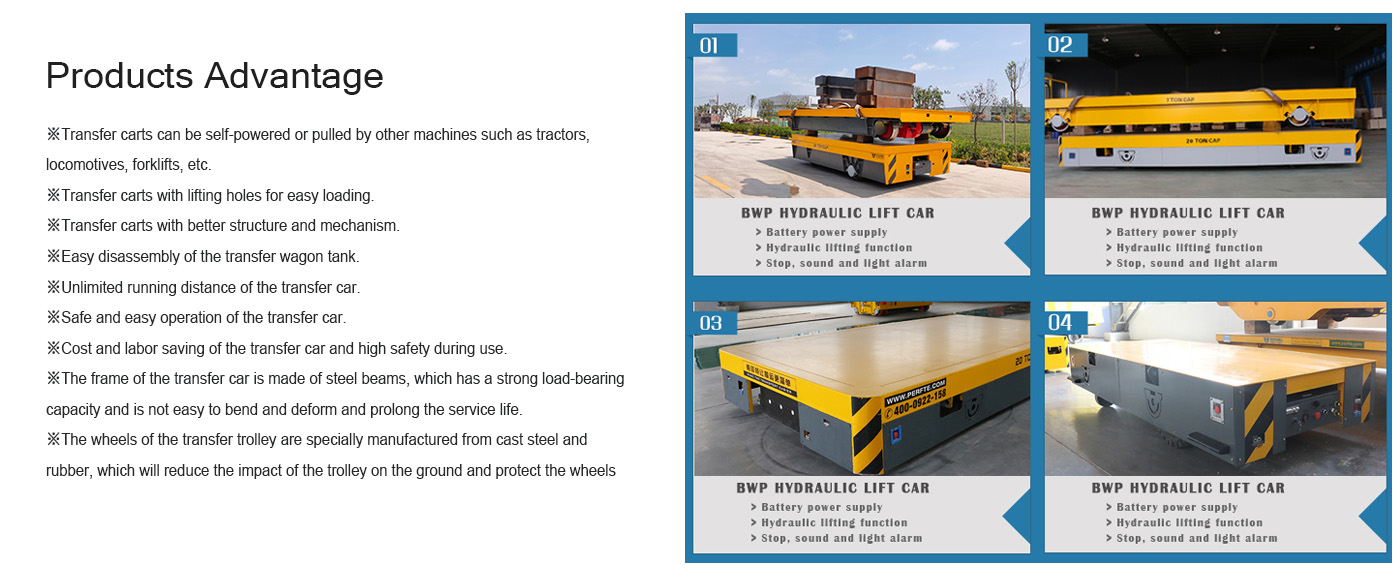

Automated Guided Vehicle Steerable Transfer Cart Mecanum Wheel Trackless Transfer Trolley Trackless Transfer Cart For Vertical And Horizontal Movement Heavy Duty Industrial Trailers Hand Operated Electric Tow Tractor

Sheet Metal Panels for a Car Body Sheet metal is a major part of an automobile. There are 40 to 50 major panels required for a typical vehicle and are most often produced by the car manufacturer because they define the geometry and quality of the vehicle. It takes 150 to 250 die sets to produce these major body panels.

By 2030, battery electric vehicles are assumed to reach an average driving range of 350-400 km corresponding to battery sizes of 70-80 kWh. In addition to battery size, another important variable in projecting total battery capacity is the proportion of battery electric vehicles and plug-in hybrid electric vehicles in overall electric vehicle

Nov 06, 2019 · The electric vehicle industry needs to figure out its battery problem Without recycling, electric vehicle batteries could lead to mountains of waste By Justine Calma @justcalma Nov 6, 2019, 1:23pm EST

Jun 13, 2020 · “With 51,000 tons, Australia was by far the most important supplier of lithium in 2018 – ahead of Chile (16,000 tons), China (8,000 tons) and Argentina (6,200 tons).

Jan 05, 2021 · Of the 180,000 metric tons of Li-ion batteries available for recycling worldwide in 2019, just a little over half were recycled. As lithium-ion battery production soars, so does interest in recycling.

nickel is providing a much-needed reprieve for the industry as a shift towards nickel-rich battery chemistries accelerates. Currently, class 1 nickel supply suitable for battery production represents approximately half of global supply of 2.1 million metric tons (Mt) – although only 350 metric kilotons (Kt)

AGV Platform Series. Stäubli designs and manufactures premium AGV (Automated Guided Vehicle) solutions. Over the last 20 years, our AGV platforms series have delivered agile motion on the factory floor for manufacturing automation to customers worldwide. Our mission is to be the leading AGV partner for high payload applications.

May 03, 2021 · 1. Redwood Materials. Nevada-based Redwood Materials aims to become the world’s top battery recycling company. It also hopes to create a circular or ‘closed loop’ supply chain by retrieving, recycling and recirculating raw materials such as cobalt, copper and nickel from end-of-life batteries.