Feb 15, 2022 · February 15, 2022. Electric vehicle drivers will spend less time at charging stations with batteries engineered for quick refueling. Research through Argonne’s XCEL initiative has already increased by 50% the energy density — or the driving range packed into a battery — that is possible with fast charging. (Image by Smile Fight/Shutterstock.)

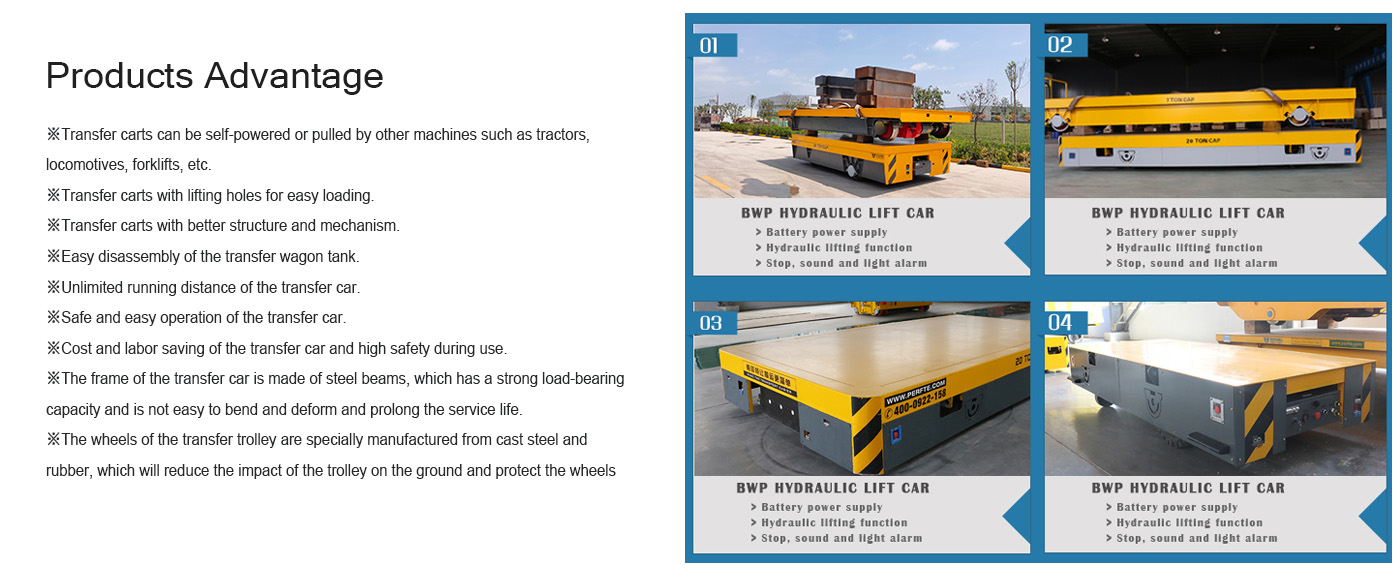

RAIL TRANSFER TROLLEY. The heavy-duty battery-powered transfer cart is composed of batteries and is the power source for a series of flatbed transfer carts. It powers the flatbed truck. The direct current flows into the distribution box and supplies the distribution box to the operating system and the motor.

2 days ago · BMW announces fresh details for the ‘New Class’. 3 Series BEV BMW Hungary. The first models of BMW’s ‘New Class’ planned for 2025, which will be designed primarily for electric cars, will be an SUV-like model and a flatter sedan based on the three-series, according to media reports. Planned production start in Hungary is 2025.

HENAN PERFECT HANDLING EQUIPMENT CO.,Perfect Transfer Cart began to manufacture in 2018, mainly producing die transfer carts,heavy duty die carts,coil transfer cart,material transfer cart,battery powered transfer cart,trackless transfer cart,cable transfer cart and industry trailer, serving 50+ countries in the world.

Fork Truck Battery Transfer Platforms with Caster 4000 Lb. Capacity Yellow: Uniform Capacity (lb.): 4,000 Usable Width/Length (in.): 31-1/2 x 40-5/16: 303: BTC-CART-WINCH : 90 Days Limited Warranty: Fork Truck Battery Transfer Platforms with Winch and Caster 4000 Lb. Capacity Yellow: Uniform Capacity (lb.): 4,000 Winch Pulling Capacity (lb.): 1,200: 299: BTC-PJ

PERFECT’s lithium battery powered industry track custom transfer cart, also known as cross flat cart, transfer trolley,electric flat cart, have advantages as simple structure, easy operation and maintenance,large load capacity and so on,with which these transfer carts are widely used in machine manufacturing and metallurgical factory matching up with lift cranes to transport heavy objects

Transfer Carts Made in China--Perfect Transfer Carts. 30 ton on-rail transfer carts. 2021 - 06 - 09. Vance Creek Railriders – Pedal The Rails! If you require assistance with our online reservations please email (our preferred contact method) info@vcrailriders.com or call between the hours of 8:30 am and 5 pm Monday-Friday (541)519-4200.

Sep 11, 2018 · In 2010, the most optimistic cost forecast for profitable production as of 2021 was $270 per kWh. The 2018 figure is already 28% lower than the 2010 prediction. On the basis of current estimates, the price of a battery pack for a midsize car will range from $7,600 to $10,700 in 2021.

Battery power electric rail car for steel mill. Storage battery of 24v, 36v, 48v supplies electricity to the dc motor. Then dc motor drives the battery transfer car to start, stop, go forward and backward and adjust its speed.

Jan 14, 2022 · As production nears, and the first units look set to roll up outside customer houses in April or May, The Register caught up with company co-founder and CMO Merlin Ouboter about the ups and downs of bringing the vehicle to market. With the production line taking shape, the biggest problem is all too familiar – getting the parts required.

2 days ago · “We ultimately see a whole range of products all based on this common next-generation electric vehicle platform. At Arcimoto we started production in 2019 right before the pandemic hit. We’ve

Sep 28, 2021 · The Volkswagen ID.4 electric vehicle (EV) is set begin localized production in the United States in early 2022. The MEB-platform, 2-row SUV will share an assembly line with the MQB-based 3-row Atlas SUV, both rolling off the line at Volkswagen of America’s (VOA) Chattanooga, Tennessee facility. Being an EV and using a different architecture

PERFECT’s lithium battery powered industry track custom transfer cart, also known as cross flat cart, transfer trolley,electric flat cart, have advantages as simple structure, easy operation and maintenance,large load capacity and so on,with which these transfer carts are widelyCustom in machine manufacturing and metallurgical factory matching up with lift cranes to transport heavy objects warehouse across.The rail transfer carts are suitable for various industries, steel mill and factor

A wide variety of platform transfer cart options are available to you, such as manufacturing plant, construction works and building material shops.You can also choose from 1 year, 2 years platform transfer cart,As well as from not available, {2}, and {3}. and whether platform transfer cart is motor, plc, or engine.

Battery module production over four plant areas. The production line is divided into four main areas. In the first section the battery cells are tested and prepared for assembly. In the second plant section, a so-called raw module is produced by use of multiple battery cells. The cells are combined into a stack in the " merging device ".